For the M2 model the plane just above the tracks is a good starting point. I began with a rectangle of plastic the width of the model but longer than that required. I will build the tank’s upper works on top of this plate, and the lower works on the bottom of this plate. This plate forms the foundation of the model, so make it out of heavy stock, in this case, 40 thou sheet.

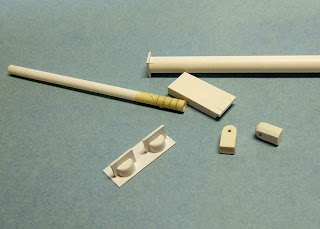

Picture 1 Starting Point: Shows the base plate. It is probably as easy to build two models as to build one, so construction was started on two vehicles. Also shown here is the upper deck.

The upper deck was scaled off the drawings and drawn out straight onto the plastic sheet. Since the turret will mount on this deck, it and the spacers supporting it, were cut from the heavier 40 thou sheet.

Picture 1A Turret Deck: This shows the upper deck plate. Note the arrow and the correction in the upper right corner. While the basic rule is measure twice, cut once, most things can be corrected as the project moves along.

Picture 2 Assembly One: Shows a “front view” of the basic assembly. I use Testors liquid Plastic Cement for the styrene parts. The forward part of the base plate is much longer than required; it will be trimmed in following steps.

Picture 3 Plans on Materials: Since we have scale drawings, parts can be measured on the drawings and transferred to your stock. This is the left and right sides for the rear of the vehicles and since this is ‘skin’ and not structure, it is lighter 20 thou plastic card. Two vehicles: so two lefts and two rights, two ups and two downs, as the depth of the rear structure is not half way! Keep your left/right and up down spacing correct. Laying them out as a group ensures equal measurements. Note the double line where a measurement was checked and corrected. The trick then is to remember which line to cut. If a piece is miss cut, it is usually best to discard it and cut again, rather than fiddling to fix it.

Picture 4 Side Plates: Here we start to “skin” in the upper structure. The ‘octagonal’ crew compartment is skinned in and the side panels are mounted. Note the reinforcement bit on the upper right. Try to get a tight corner along the edge of the base plate. Notice too, the side plate sits on top of the base plate but the top plate is inside the side bit. Basically the purpose of the base plate is also to preserve the dimensions of the vehicle, providing a straight line from the front fenders to the side plates.

Picture 5 Lower Hull: Here, side plates for the lower hull are sketched out. These side plates will support the tracks so they are also heavy stock.

Picture 6 Lower Hull Two: The model itself forms part of your building plans. The underside of the base plate is marked for a centre line and the position of the lower side plates. A line across the vehicle marks the rear edge of the crew compartment and references measurements front to back.

Picture 7 Lower Hull Three: This photo shows the lower hull plates assembled with a rectangular lower plate. Also installed is a lower glacis plate, and part of the “pyramid”. Using a top view of the drawing the width of the pyramid plate at the upper glacis can be determined. The length of the angled plate can be taken from a side view of the vehicle. -At this point, you are into the world of ‘as-builts” if your model is not to the scale or size you want, it is probably best to start over before you do too much work. Otherwise, use the model to determine the dimensions of the parts. It is as you built it. The width of the front glacis is the width measured on the model. What I have done here is trim the front portion of the base plate to leave the front fenders sticking out. I then trim the plate to allow the front glacis to assume its natural angle. It will be very close to the drawing and it’s up to you how close you need it to be. For me, this is close enough.