Picture 29 Hull Details: While the track assemblies dried (Don’t rush them—when in doubt give it overnight to dry.) I was adding details to the hulls and turrets. Here plastic strips add detail to the glacis, rear deck and machinegun turrets. Some thin sheet forms the side and top crew compartment doors.

Picture 30 Hull and Tracks: Here a hull awaits

attachment of the suspension units.

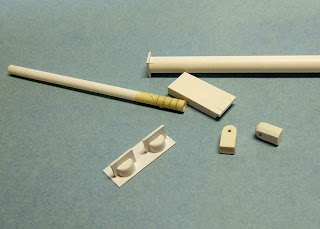

Picture 31 Tubes and Cylinders Two: But first some

more do-dads: the transmission covers and return wheel supports. Thicker plastic can be built up by laminating

thinner sheet. Thicker ends on tubes can

be sanded to create curve or domed tube-ends or caps.

Picture 32 Suspension Details: A closer look

at building complex looking parts out of basic shapes and layers.

Picture 33 Mounting the Tracks: The tracks are

then mounted with a transmission bit at the front and return wheel support at

the back.

Picture 34 Mantlet: A thick block of laminated plastic was

carved into the shape of the mantlet.

This was then pushed into a ball of green stuff. The original was pulled out before the green

stuff dried. Lower right is the plastic

original, and lower left the green stuff mould.

When cured, the interior of the green stuff mould was wetted down with

some water and ‘squashed onto a blob of fresh mixed green stuff. The two paint

jars each have a formed mantlet.

Originally a squash mould was planned for the bogies, but the technique

does not provide of a lot of detail. Latex

moulds are sufficient for the Alumilite.

RTV moulds would probably be a better quality option but are more

expensive.

Picture 35 On Tracks: The two tanks are shaping up nicely. The mantlets were trimmed, sanded and

installed. Some brass rod will be used

for the guns and machineguns.

No comments:

Post a Comment